DC Motor Speed and Direction Control

1 in stock

DC Motor Speed and Direction Control

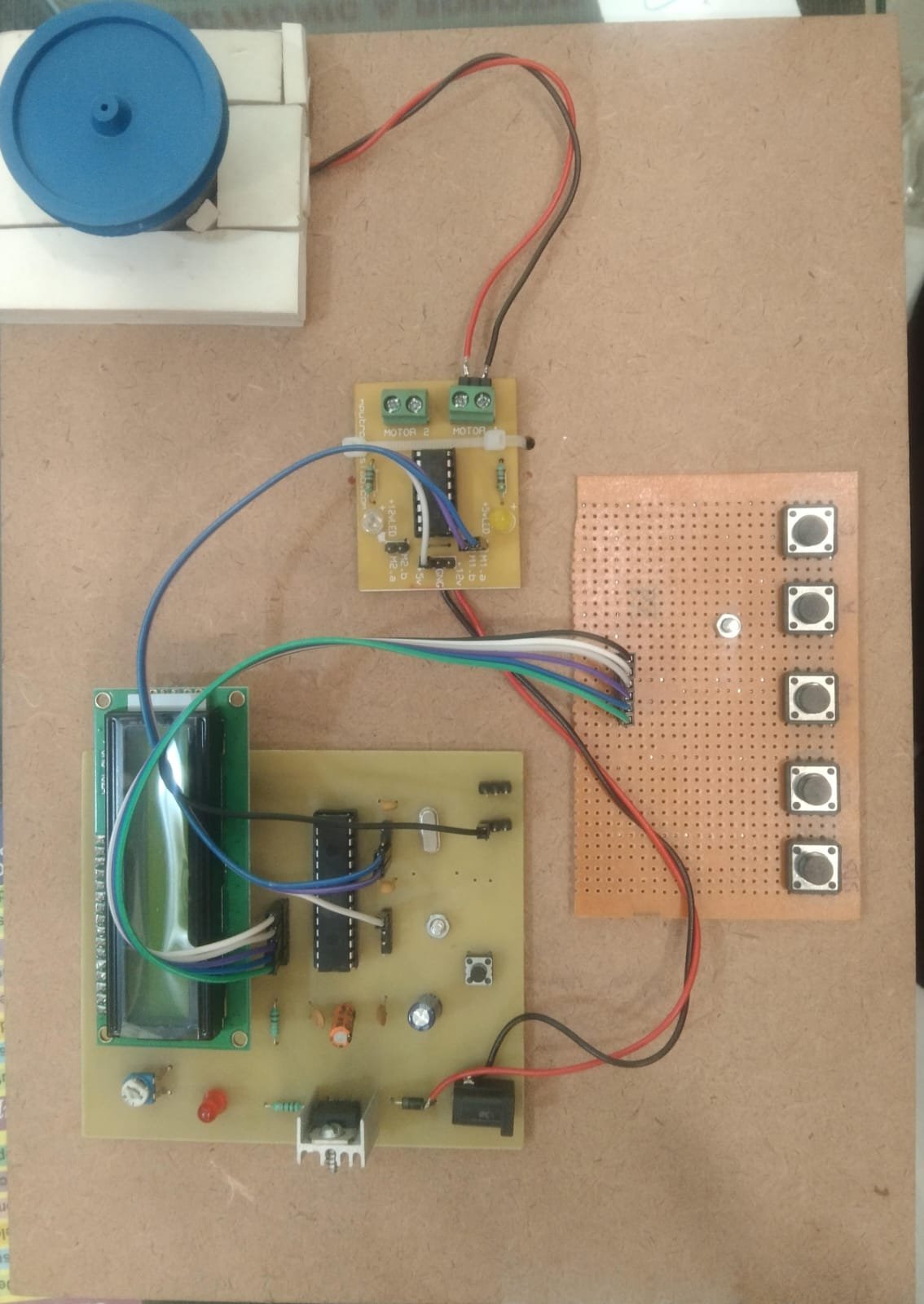

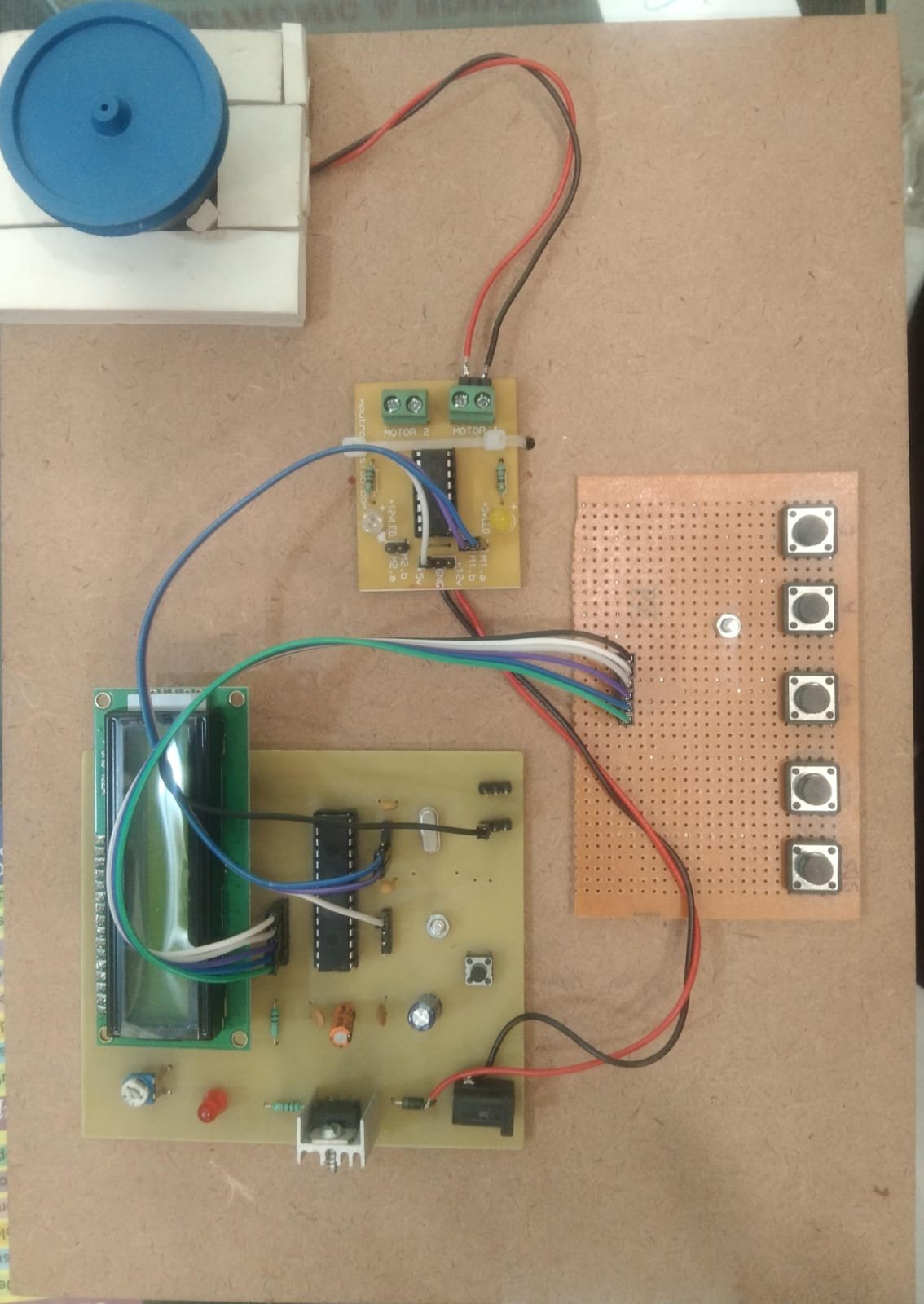

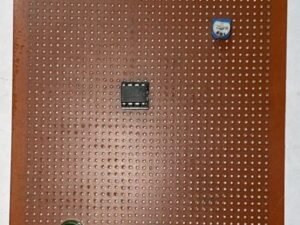

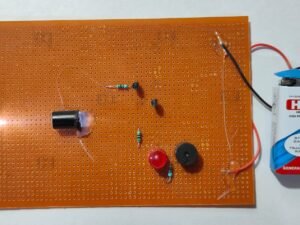

Controlling the speed and direction of a DC motor is essential in robotics, automation, and various electronic systems. This project demonstrates how to control a DC motor’s speed and direction using a microcontroller (like Arduino), an H-bridge motor driver (such as L298N or L293D), and PWM (Pulse Width Modulation).

₹3,481.00 ₹4,130.00 (Incl. GST)

1 in stock

DC Motor Speed and Direction Control

Controlling the speed and direction of a DC motor is essential in robotics, automation, and various electronic systems. This project demonstrates how to control a DC motor’s speed and direction using a microcontroller (like Arduino), an H-bridge motor driver (such as L298N or L293D), and PWM (Pulse Width Modulation).

⚙️ Working Principle

-

Speed Control using PWM:

-

PWM is a technique used to vary the average voltage supplied to the motor by switching it ON and OFF rapidly.

-

The higher the duty cycle (ON time), the faster the motor rotates.

-

Arduino can generate PWM signals using the

analogWrite()function.

-

-

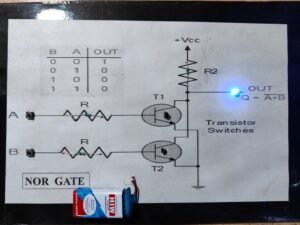

Direction Control using H-Bridge:

-

An H-bridge is an electronic circuit that allows voltage to be applied across a load in either direction.

-

It consists of 5 switches/transistors; by changing their states, the current flow through the motor can be reversed.

-

L298N and L293D motor drivers make this easy by providing input pins to control direction and enable pins for speed control.

Typical Connections:

-

IN1 and IN2 control direction (e.g., IN1 HIGH & IN2 LOW = Forward)

-

ENA (Enable pin) controls speed using PWM

-

Arduino takes user input (e.g., from a potentiometer or buttons) and adjusts motor behavior accordingly

💡 Applications:

-

Robotics (line follower, obstacle avoidance)

-

Conveyor belts

-

Smart home devices (curtains, fans)

-

Electric vehicles

✅ Advantages:

-

Precise control over motion

-

Easily programmable and scalable

-

Can be expanded for dual motors or remote control

-

-