Vibration Sensor

6 in stock

A vibration sensor measures and monitors vibration levels in machinery and structures. Common types include piezoelectric sensors, accelerometers, and proximity probes. They are crucial for predictive maintenance, structural health monitoring, and various industrial applications, ensuring equipment health and safety by detecting imbalances, misalignments, and potential failures.

₹78.59 ₹153.40 (Incl. GST)

6 in stock

Vibration Sensor

A vibration sensor is a device used to measure and monitor the vibration levels in machinery, equipment, and structures. These sensors play a crucial role in predictive maintenance, structural health monitoring, and various industrial applications by providing real-time data on the vibrational behavior of different systems.

Types of Vibration Sensors

- Piezoelectric Vibration Sensors:

- These sensors use piezoelectric materials that generate an electrical charge in response to mechanical stress.

- They are known for their high sensitivity and wide frequency range.

- Commonly used in industrial applications for machinery monitoring.

- Accelerometers:

- Accelerometers measure the acceleration forces acting on a body, which can be used to calculate vibration.

- They come in different types, including capacitive, piezoelectric, and MEMS (Micro-Electro-Mechanical Systems) accelerometers.

- Widely used in applications ranging from smartphones to aerospace.

- Proximity Probes:

- These sensors measure the displacement between a probe and a target surface.

- Often used in rotating machinery like turbines and compressors to monitor shaft vibration.

- Velocity Sensors:

- Measure the speed of vibration directly.

- Suitable for medium to low-frequency applications.

- Often used in structural monitoring and geophysical applications.

Applications of Vibration Sensors

- Predictive Maintenance:

- By monitoring the vibration levels of machinery, vibration sensors help in predicting equipment failures before they occur.

- This enables maintenance teams to schedule repairs during planned downtimes, reducing unplanned outages and increasing the lifespan of machinery.

- Structural Health Monitoring:

- Vibration sensors are used to monitor the integrity of bridges, buildings, and other structures.

- They detect changes in vibration patterns that may indicate structural damage or degradation over time.

- Automotive Industry:

- Used to monitor the performance and health of engines, transmissions, and other components.

- Helps in detecting imbalances, misalignments, and other issues that can lead to mechanical failure.

- Consumer Electronics:

- Incorporated into devices like smartphones, gaming controllers, and fitness trackers to provide feedback and enhance user experience.

- Aerospace and Defense:

- Used in aircraft and spacecraft to monitor vibrations and ensure the structural integrity of critical components.

- Helps in identifying potential issues that could affect safety and performance.

Key Considerations

- Sensitivity and Frequency Range:

- The choice of a vibration sensor depends on the specific application requirements, including the sensitivity and frequency range needed.

- Mounting and Installation:

- Proper mounting is essential for accurate measurements. The sensor should be securely attached to the surface being monitored.

- Environmental Factors:

- Vibration sensors must be selected based on the operating environment, considering factors like temperature, humidity, and exposure to chemicals or dust.

- Calibration and Maintenance:

- Regular calibration is necessary to ensure the accuracy of vibration measurements.

- Maintenance involves checking the sensor and its mounting for any signs of wear or damage.

In conclusion, vibration sensors are indispensable tools in various industries, providing critical data that helps in maintaining equipment health, ensuring structural integrity, and enhancing performance. Their versatility and reliability make them essential for modern predictive maintenance and monitoring systems.

| Weight | 0.00 kg |

|---|---|

| Dimensions | 0.00 × 0.00 × 0.00 cm |

Related products

-

Sensors and Modules

Relay Module 4 Channel 5V

0 out of 5(0)The Relay Module 4 Channel allows for controlling multiple high-voltage devices using low-voltage signals. Featuring four relays with independent channels, it supports up to 10A at 250V AC. Ideal for automation projects, it includes optocoupler isolation for safety and LED indicators for easy monitoring.

SKU: relay-module-4-channel -

Sensors and Modules

Bluetooth Module HC05

0 out of 5(0)The Bluetooth Module HC05 is a versatile and easy-to-use module for enabling wireless communication between devices. It supports both master and slave modes, allowing for flexible pairing with other Bluetooth devices. Ideal for Arduino and microcontroller projects, it facilitates data transfer, remote control, and wireless connectivity in various applications, from home automation to robotics.

SKU: bluetooth-module-hc05 -

Sensors and Modules

MQ9 Sensor

0 out of 5(0)The MQ9 sensor detects carbon monoxide and combustible gases like methane and LPG. It offers high sensitivity, fast response time, and both analog and digital outputs. Widely used in industrial safety, home gas detectors, and air quality monitoring, it ensures reliable detection and efficient monitoring of harmful gases.

SKU: mq9-sensor -

Sensors and Modules

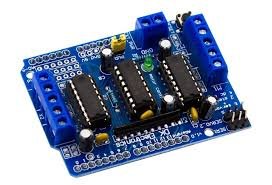

Motor Driver Shield L293D

0 out of 5(0)The Motor Driver Shield L293D is an essential Arduino accessory, enabling control of up to four DC motors or two stepper motors. With dual H-bridge motor drivers, PWM control, and stackable design, it’s ideal for robotics, automation, and prototyping, offering versatility, ease of use, and affordability.

SKU: motor-driver-shield-l293d